![]()

After Jackson State University’s ENGAGE center was unveiled Thursday in the basement of the H.T. Sampson Library, the campus community can now envision President Carolyn W. Meyers, perhaps, one day tooling around town in a car built in just 24 hours by students using 3-D technology.

It’s not as far-fetched as it sounds.

The free use of 3-D scanners by JSU students and the public puts innovators in the driver’s seat to making an “instant automobile” a reality.

In fact, the technology already exists, and JSU is jumping on the bandwagon. Indeed, the campus is on the cusp of an extraordinary development reminiscent of “Transformers,” a science-fiction thriller in which alien robots undergo a rapid metamorphosis by turning into automobiles.

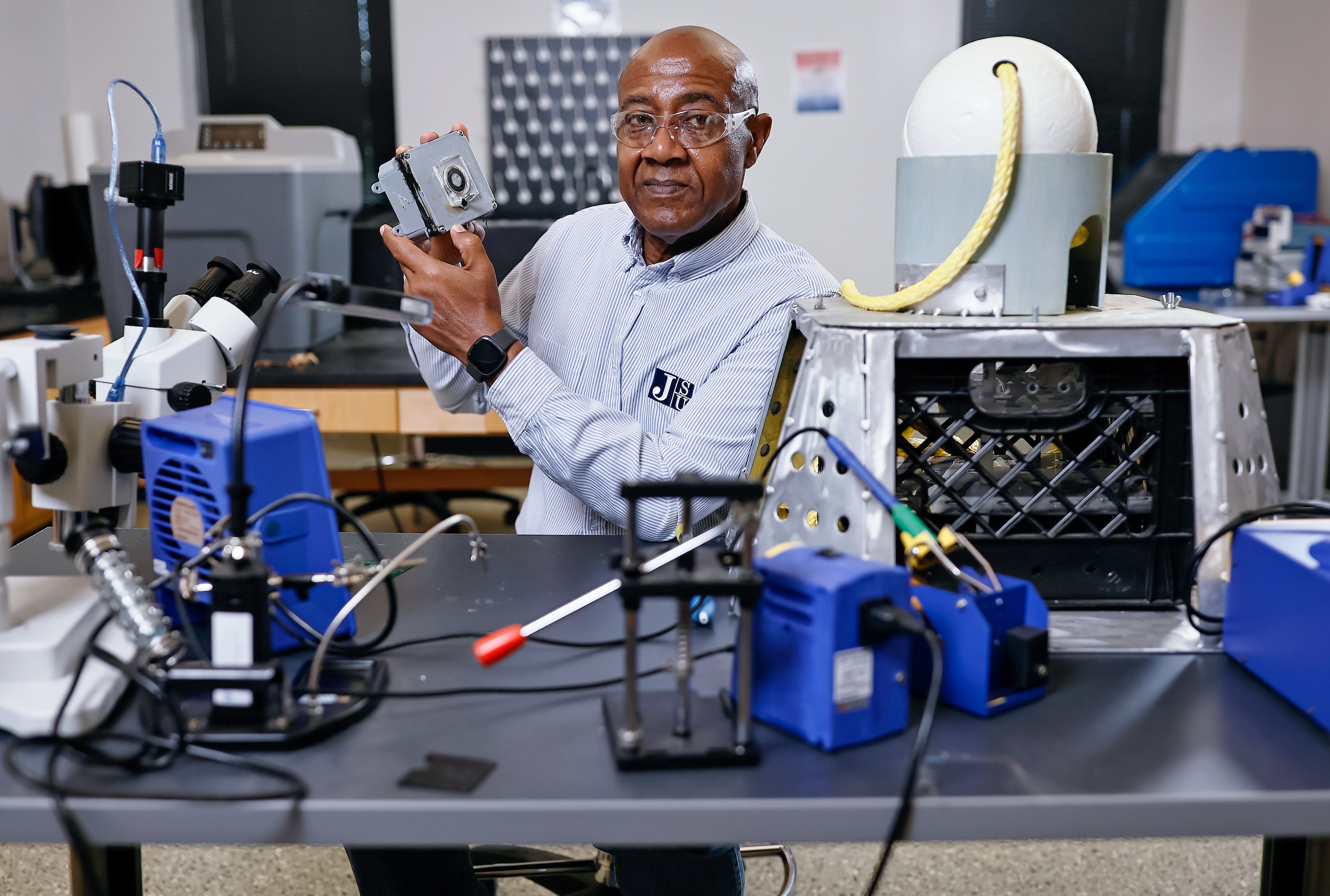

[dropcap]D[/dropcap]R. Robert Blaine, dean of Undergraduate Studies and CyberLearning at JSU, explained this new reality while a group of faculty, staff and students observed a plastic vase being constructed from a computer image connected to a 3-D printer.

“One of the projects we’re looking at for students is 3-D printing a bunch of electric motors to see if we can get a car to run,” Blaine said. He indicated that one company called Local Motors (localmotors.com) of Tempe, Ariz., is already engineering a functional automobile that exceeds Federal Motor Vehicle Safety Standards.

“The company will build custom cars; you send your own design, and it will 3-D print the car,” he said.

Innovation such as this would force manufacturers to reconsider the prudence of mass production versus customized production.

Blaine said some experts, using a giant machine, have successfully “3-D printed an automobile within 24 hours and driven it. … They printed out the car in about five parts, put it together, placed an electric drivetrain on it with an aluminum frame, and they drove it out of the shop.”

Last summer, USA Today reported that a recent 3-D design by Local Motors required only 50 parts while a typical car has 25,000 parts.

“Bottom line,” said Blaine, “is that there literally is nothing you can’t build with 3-D technology.” He said such cars are made from waste material, or pellets, from the production of carbon fiber that is then embedded into plastic.

“For Jackson State, the amazing thing about all of this is that you can go from the classroom to the market in just one step – from the theoretical to implementing to prototyping and then to market.”

Meanwhile, Meyers said, “The ENGAGE center helps distinguish Jackson State University from the 4,000-plus other institutions of higher education in this country.”

Paraphrasing renowned author and computer professor Richard A. DeMillo of the Center for 21st Century Universities, Meyers said, “We’re at an inflection point in the evolution of higher learning globally. We know more about how the brain works and how people learn. We have more information and tools and technology than ever before … to effectively transfer knowledge, create new knowledge and make this a better place.” She urged the audience of professionals and students to lead the revolution advancing technology and remain on the forefront of “educational delivery.”

Asked how 3-D technology would impact the labor force, Blaine said it will transform the industry, and some people will have to retool their skills. “If you look at the auto industry even now, the number of hands that touch a car being made is a tenth of what it used to be. The real jobs of the future are for the people who program the machines that actually do the work. If our students move to the forefront of this, they will be the ones leading the way the industry goes rather than being left behind.” He said while there will be fewer jobs “there also will be a more highly educated workforce. Those who are able to take advantage of that will thrive.”

[dropcap]S[/dropcap]O, how is this new technology being accomplished?

Blaine said the manufacturing sector is using 3-D printers made of giant machines known as Computer Numerical Control (CNC) devices that command computers to operate machine tools.

While JSU is not at that level yet, the future is quite promising. So instead of building cars right now, the audience watched in amazement how a machine could churn for nearly an entire day to produce a tall vase from a mere computer image. The 20-hour process had 16 more hours left for completion. Blaine said the head of the device dispensing the material for the vase is heated about “220 degrees Celsius,” which is 428 degrees Fahrenheit. The heat is so intense that the plastic becomes liquid. Another aspect of this development is that various colors can be added.

The vase in progress that thrilled the campus audience was being developed by biodegradable plastic known simply as PLA – polylactic acid (actually polyester). It’s the same type of inexpensive material (string) used with a weed wacker.

JSU also has 3-D printers that can support stronger, more expensive plastics such as carbon fiber and Kevlar (a synthetic fiber that can be used to manufacture tires, helmets and even vests that can stop bullets and knives). In other words, Kevlar (and carbon fiber) “are lighter than steel, yet stronger than steel,” Blaine said. Some sources even describe Kevlar as “five times stronger than steel on an equal weight basis.”

Blaine said art museums also are showing practical uses for 3-D scans by creating replicas for the public of their most fragile and precious exhibits.

In explaining why the use of 3-D printers is free to students and the public, Blaine said, “The whole idea is that this is about learning. When you’re in the ENGAGE center creating something that’s what we pay for, and that’s our job.” In addition, said Blaine, “This technology can be used in any discipline. We’re not just doing 3-D printing but also 3-D imaging, such as certifications for students of CAD (computer-aided design).” He said imaging is also effective for building a 3-D movie scene on a computer for film productions.

[dropcap]W[/dropcap]ITH its newest ENGAGE center, JSU continues to be on the cutting edge of innovation and technology.

More than two years ago, the university began implementing new strategies and methods for improving the skills of faculty, staff and students.

Its INNOVATE center was established to redesign the way curriculum is viewed; its CREATE center reassesses solutions to big problems; now, its ENGAGE center is about making an idea or product active.

Blaine said the final piece, which will start in the fall, will involve transforming instructional methods used by faculty. This process involves the launching of a digital teaching and learning academy for improving the communication processes between faculty and students and assessing the methods of learning.

Blaine said the takeaway from the ENGAGE unveiling is that “we’re transforming learning at Jackson State.”

Finally, he said, “We’re looking at creating today’s learner for tomorrow’s future. The only way we can do that is to engage students with new technology of today and influence the world of today to change its pedagogy to create a different kind of thinker for a new world.”